Sack Automation

Sack Automation solutions from The Sack Filling and Robot Palletising Company reduce or eliminate the need to manually perform repetitive tasks allowing for a more efficient deployment of labour.

Typically the combination of a Bagging Machine, Sack Placer, Sack Top Control System and either a Fixed Head Stitching solution or Heat Sealer can allow a packing line to be run by a single operator.

Sack Top Control Systems

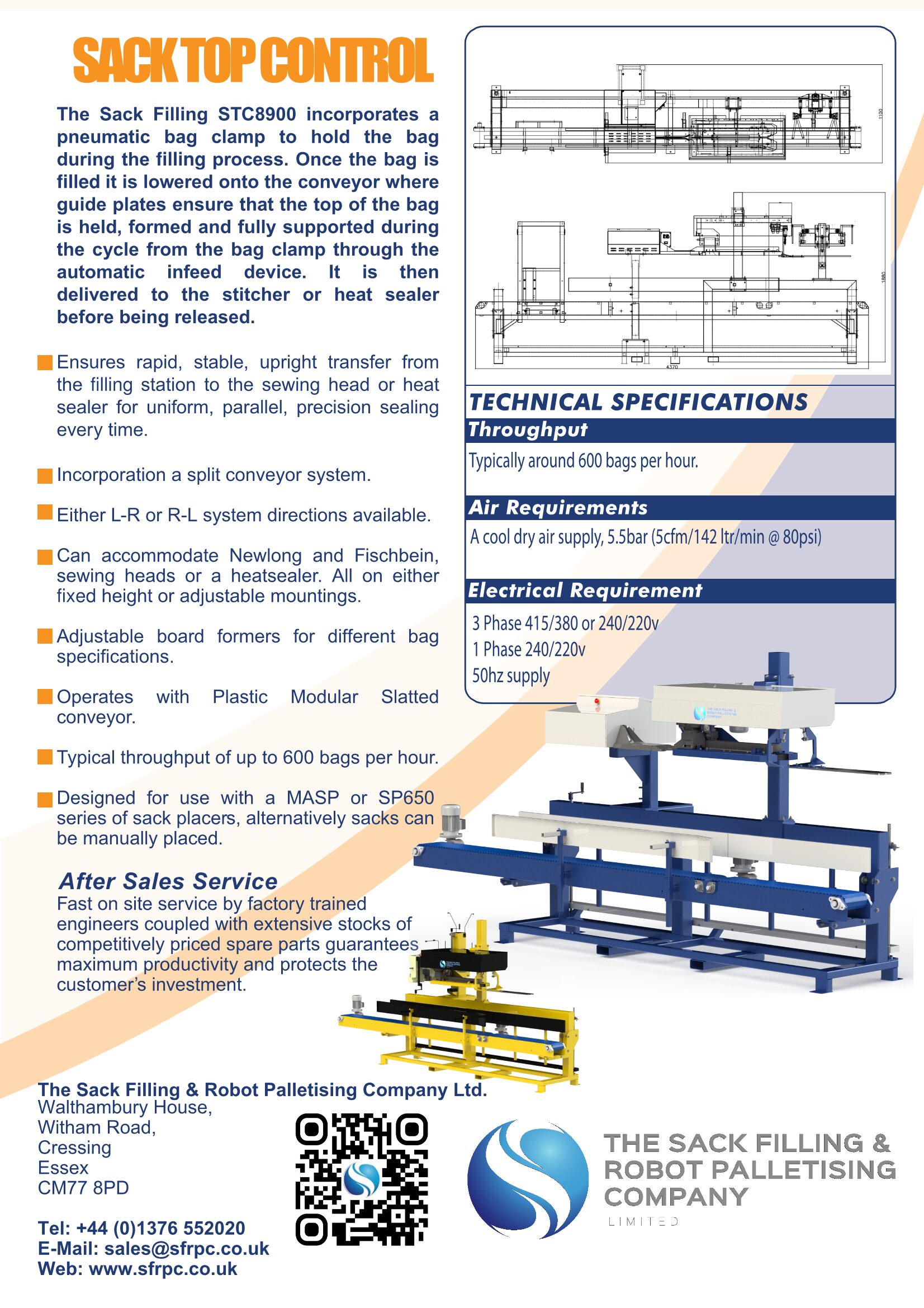

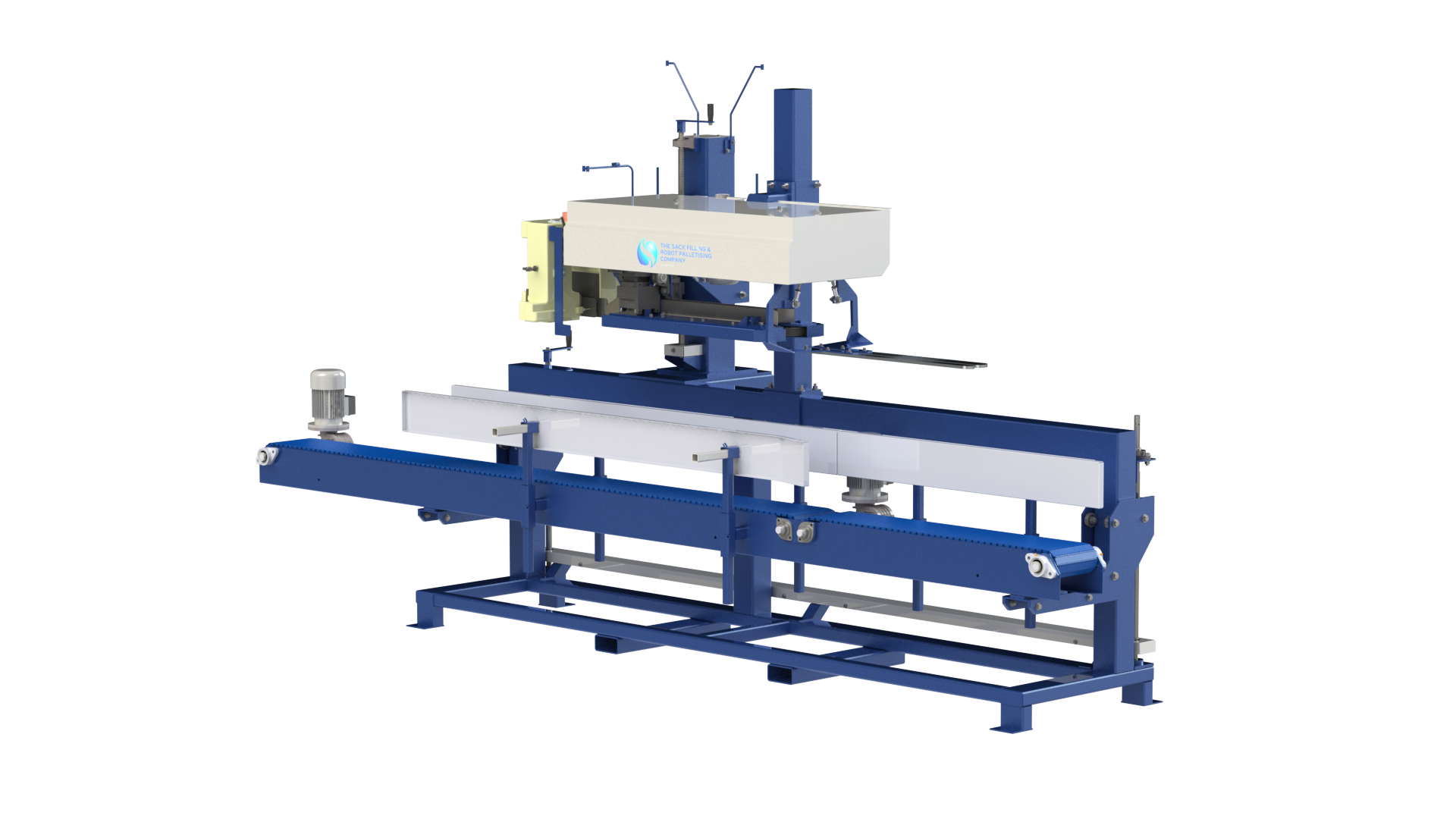

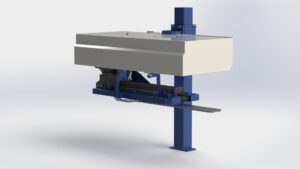

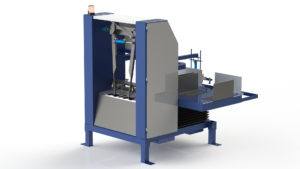

STC 8900 High Speed Sack Top Control

STC 8900 High Speed Sack Top Control

The STC8900 incorporates a pneumatic bag clamp to hold the bag during the filling process. Once the bag is filled it is lowered onto an Intralox conveyor, at the same time two spreader fingers descend with the sack and spread the sack top.

Two support arms then hold the sack top in the spread position and convey the filled sack foward to the stitcher or heat sealer before being released. The sack is supported at all times during this cycle to ensure a even, uniform seal every time.

Key Benefits

- Up to 12 bags per minute depending on material and bag type.

- Ensures rapid, stable, upright transfer from the filling station to the sewing head or heat sealer for uniform, parallel, precision sealing every time.

- Full pneumatic operation with PLC control for reliability.

- Either L-R or R-L system directions available.

- Can accommodate Newlong, Fischbein, Union Special and Reed Medway sewing heads or a heatsealer. All on either fixed height or adjustable mountings.

- Adjustable guide boards for different bag specifications.

- Operates with Intralox flat track conveyor.

- Designed for use with WASP or WASP Lite sack placer, alternatively sacks can be manually placed.

- Entire sack top control system mounted above the conveyor on one robust chassis leaving floor area clear.

- Can be used with existing gross or net weighers.

- Fitted with either a Newlong NP7A or DS9C head as standard.

Automatic Sack Placers

The Sack Filling Companies range of Sack placing solutions reduce the need for operator input at the bagging head. Sacks are placed rapidly and accurately to maintain a uniformity of fill and seal of the bag.

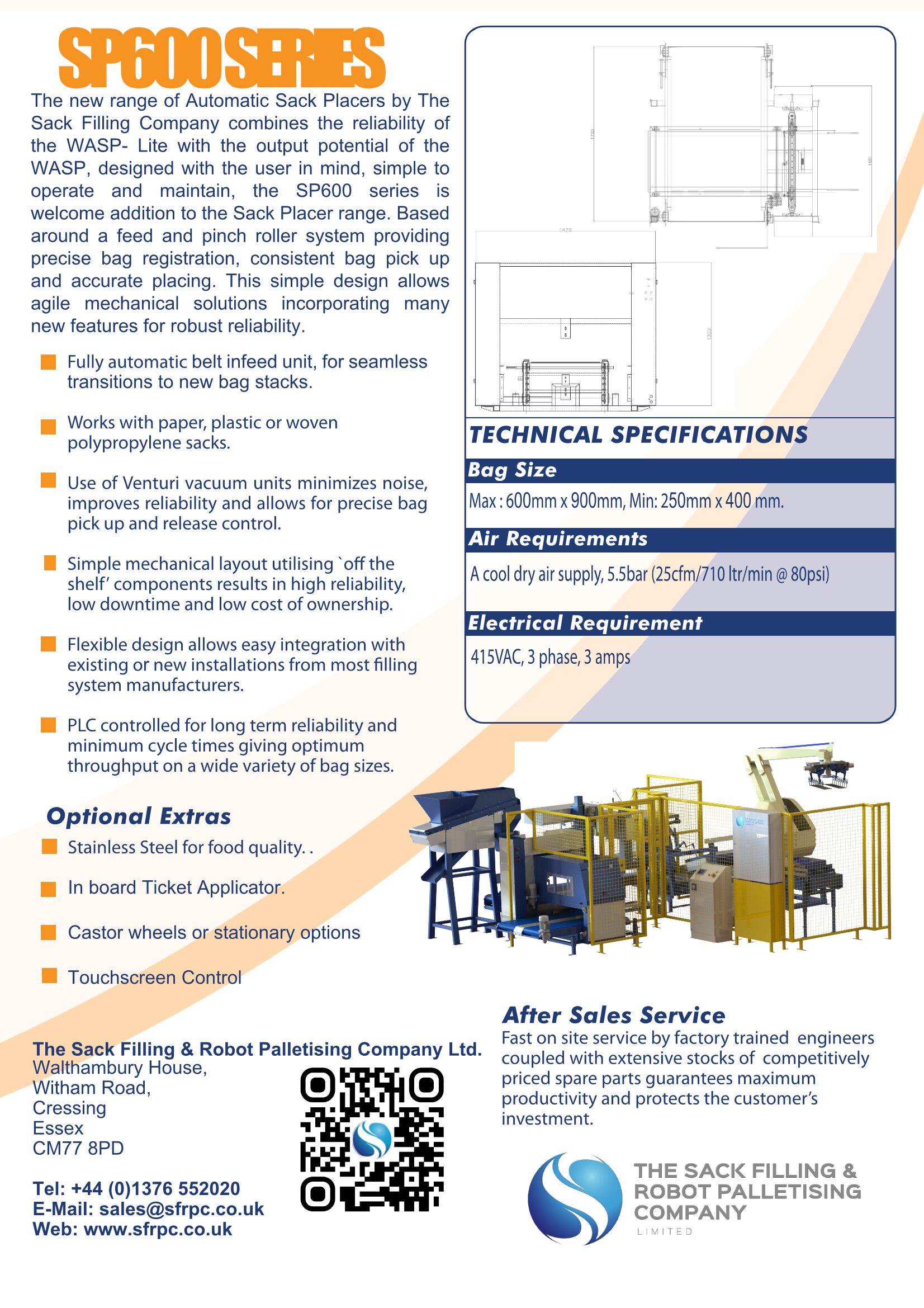

SP650 Automatic Sack Placer

SP650 Automatic Sack Placer

The new range of Automatic Sack Placers by The Sack Filling Company combines the reliability of the WASP- Lite with the output potential of the WASP, designed with the user in mind, simple to operate and maintain, the SP600 series is welcome addition to the Sack Placer range. Based around a feed and pinch roller system providing precise bag registration, consistent bag pick up and accurate placing. This simple design allows agile mechanical solutions incorporating many new features for robust reliability.

Optional Extras

- In board Ticket Applicator.

- Stainless Steel for food quality.

- Castor wheels or stationary option.

Key Benefits

- Paper, plastic or woven polypropylene bags.

- Up to 10 bags/min - dependant on material/product.

- Easily integrated with existing or new installations.

- Automatic 2 x 200 (400 bag) magazine.

- P.L.C. controlled

M958 Wathambury Automatic Sack Placer (WASP)

M958 Wathambury Automatic Sack Placer (WASP)

Based around a feed and pinch roller system providing precise bag registration, consistent bag pick up and placing. This simple design, agile mechanical solution incorporate many features for robust reliability.

Optional Extras

- Stainless Steel for food quality.

Key Benefits

- Paper, plastic or woven polypropylene bags.

- Up to 10 bags/min - dependant on material/product.

- Easily integrated with existing or new installations.

- Automatic 2 x 200 (400 bag) magazine.

- P.L.C. controlled