Conveying Systems

The Sack Filling & Robot Palletising Company’s range of conveying equipment are tailored to our customers requirements from pallets to powders and boxes to bags, we can accommodate any conveying and handling needs.

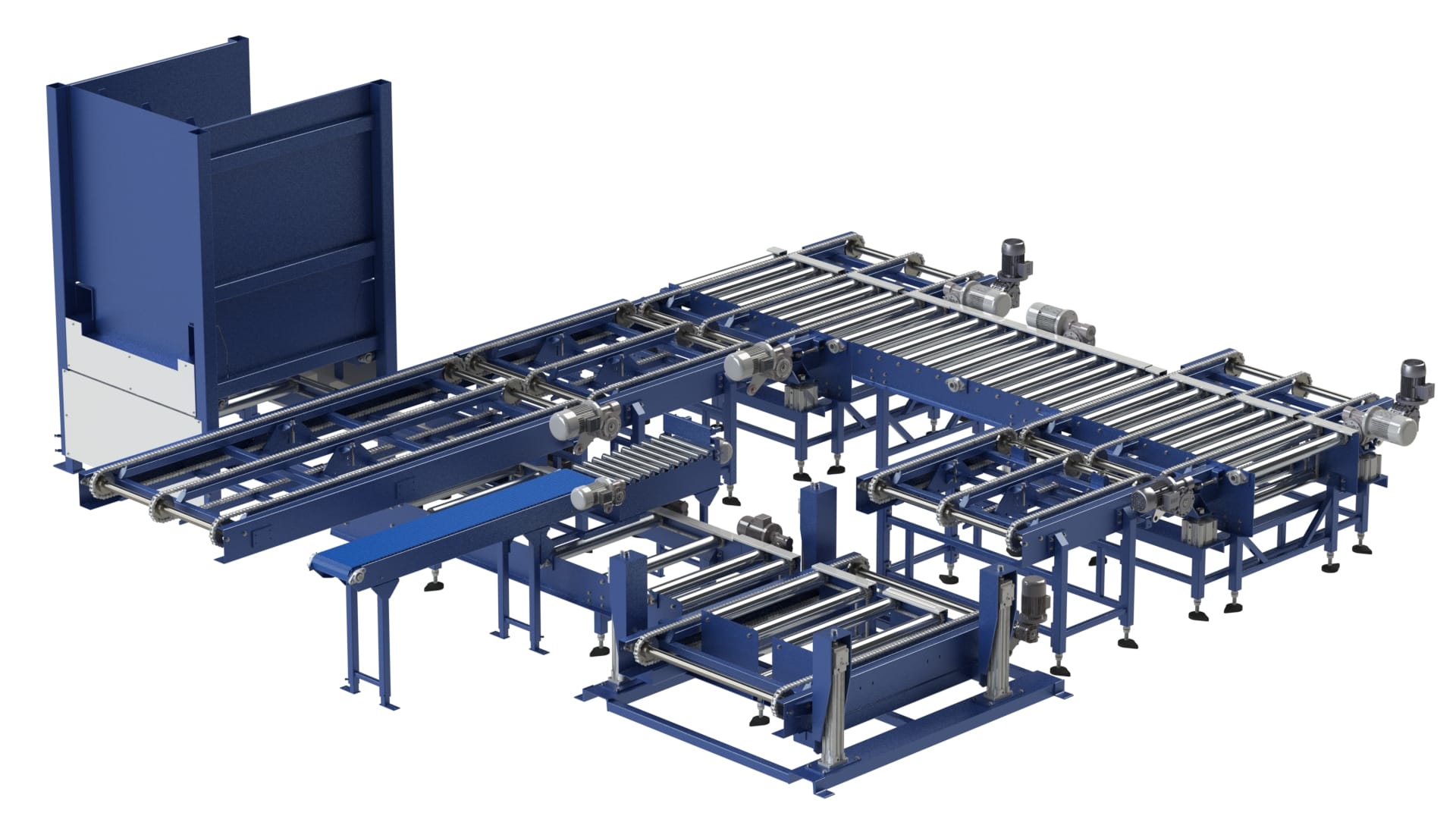

Pallet & Box Conveying Systems

Pallet and box conveyors are tailored to length, width and control configuration to suit the requirements of any material transport system- from simple stitching lines to fully automated production and packing facilities. All pallet and box conveyors are available in rubber belt, Intralox®, stainless steel slat band and plastic slat band to meet the needs of your product.

Key Features

- Heavyweight steel (or stainless steel) construction with sealed bearing units

- Torque direct mount or chain drive motor/gearbox unit

- Complete with all electrical control gear

- Simply integrated into existing plant layout

- Standard 2, 3, 4 and 5 meter lengths, custom lengths on request

- Complete system design service

Optional Extras

- Special speed versions via chain drive or continuously variable speed motor/gearbox units

- Custom belt profiles, such as troughed belts

- Electrical and manual height adjusting units

- Add-on PLC based accumulating and indexing system

- Powered and manual roller tracks

- 1.2 metre extensions

Box and Pack Turners

Box and Pack Turners

The Sack Filling Company manufacture several units for turning packs on the conveyor from simple turning bars to pneumatically and electrically operated turners. Can be integrated into an existing or new system or supplied as a standalone unit.

Case Erection and Closing Units

Case Erection and Closing Units

The Sack Filling Company can supply case erecting and closing units to complement the filling and transport of the cases. We have supplied a complete Case erecting, plastic sack insertion, Filling machine, Sack Closing and Box Closing line for carbon materials.

Check Weighing

Check Weighing

The Sack Filling Company can supply check weighing solutions (up to 60 units per minute) and effective units, rich in advanced features such as RS Serial communication and printed reports, yet are simple by design, fully self-contained with a small operational footprint so can be integrated into existing systems effortlessly.

Optional Extras

- Stainless Steel for food quality

- Reject system to customer requirements.

- HMI Screens for ease of use.

Metal Detector

Metal Detector

Metal Detecting conveyors are a highly effective and reliable solution for detection of ferrous contaminants in boxes of product down to the smallest piece of swarf. They are able to work in close proximity to other metal structures and equipment without interference thus negating the need for a ‘metal free zone’.

Optional Extras

- Stainless Steel for food quality

- Reject system to customer requirements

Sack Conveyor Systems

Sack Conveyors are tailored to length, width and control configuration to suit the requirements of any material transport system- from simple stitching lines to fully automated production and packing facilities. All Sack Conveyors are available in rubber belt, Intralox® (right), stainless steel slat band and plastic slat band to meet the needs of your product.

Sack Turners

Sack Turners

Inline and 90 deg bag turners have a simple, rugged design allowing various sized bags to be turned to a horizontal position for removal or entry to a bag press.

Key Benefits

- Fully height adjustable

- Compact space-saving design requires minimal operating area

- PLC controlled with software tailored for customer’s requirements

- Pneumatic operation

Optional Extras

- Inline or 90 degree versions

Bag Press

Bag Press

The Sack Filling Company Bag Presses are made to the needs of the customer. Length and elevation angle can be tailored to the customers specifications or in standard roller or belt configuration

Key Benefits

- Guarding to suit customer requirements

- Stainless steel construction available.

- Optional hydraulic adjustment.

- Special ‘shoe’ press for difficult products

Optional Extras

- Variable elevator lengths

Powder Conveyor Systems

The range of Sack Filling powder conveyors includes Screw Conveyors, Aero- Mechanical Conveyors and Pneumatic Conveying Systems. All are tailored to length, width and control configuration to suit the requirements of the material transport system.

Screw Conveyors

Screw Conveyors

The range of Sack Filling Screw Conveyors vary in size from 75mm up to 400mm diameter, up to a length of 25m, light to heavy duty, manufactured in mild steel or food quality stainless steel.

Optional Extras

- Stainless Steel for food quality

Pneumatic Conveyors

The Bel-Tyne range of Pneumatic Conveying Systems include the lean phase low pressure system, negative pressure or vacuum system and the purpose designed powder pumping systems.

The Bel-Tyne range of Pneumatic Conveying Systems include the lean phase low pressure system, negative pressure or vacuum system and the purpose designed powder pumping systems.

The systems transfer powdered and granular products from infeed to outfeed points with safety and environmental regulations in the forefront of the system design. Each conveying request is used to meet the client’s needs.

Disc Lift Conveyors

Disc Lift Conveyors

The Bel-Tyne Disk Lift Aero- Mechanical Conveyor allows for the economical handling of multi- various powders, granules and capsules simply and efficiently with the minimum of degradation.

The Bel-Tyne Disk Lift Aero Mechanical Conveyor is designed to convey a wide variety of bulk materials. It is a tubular conveyor which comprises of a continuous rope assembly having plastic or rubber discs fitted at equal intervals on a wire rope supported on two uniquely shaped sprockets.

Due to the close fitting disc flight relative to the tube diameter they displace both air and material resulting in the fluidizing of the conveyed material, even material which do not have fluidizing properties are easily handled.

Due to this phenomenon the aero- mechanical is capable of very high throughput rates exceeding many other types of conveyor comparable with it’s size and power utilized.

In addition by the very nature of the conveying method minimum degradation occurs in relation to other types of mechanical conveying means.