Weighing & Bagging Equipment

Weighing and Bagging machines manufactured by The Sack Filling and Robot Palletising Company offer a great investment for any agricultural or industrial packing operation.

From high-throughput packing houses to family farms, growers and packers of any size can benefit from a bagging solution from The Sack Filling Company’s Walthambury / Morray Range. The Walthambury / Morray range can handle anything from potatoes and root vegetables to coal and other solid fuels, powders, bark chips, animal feeds, grain- almost any product you can throw at them.

Walthambury. The original agricultural Weighing, Bagging and Sack Closing systems. With a long history of engineering innovation and a rich tradition of accuracy, reliability and durability these trademark black and yellow machines are the workhorses of packing houses across the nation and the globe.

From simple Manual Bagging applications to complete packing house installations The Sack Filling Company’s Morray & Walthambury range is the perfect choice. Visit the Morray website Morray

Manual Bagging

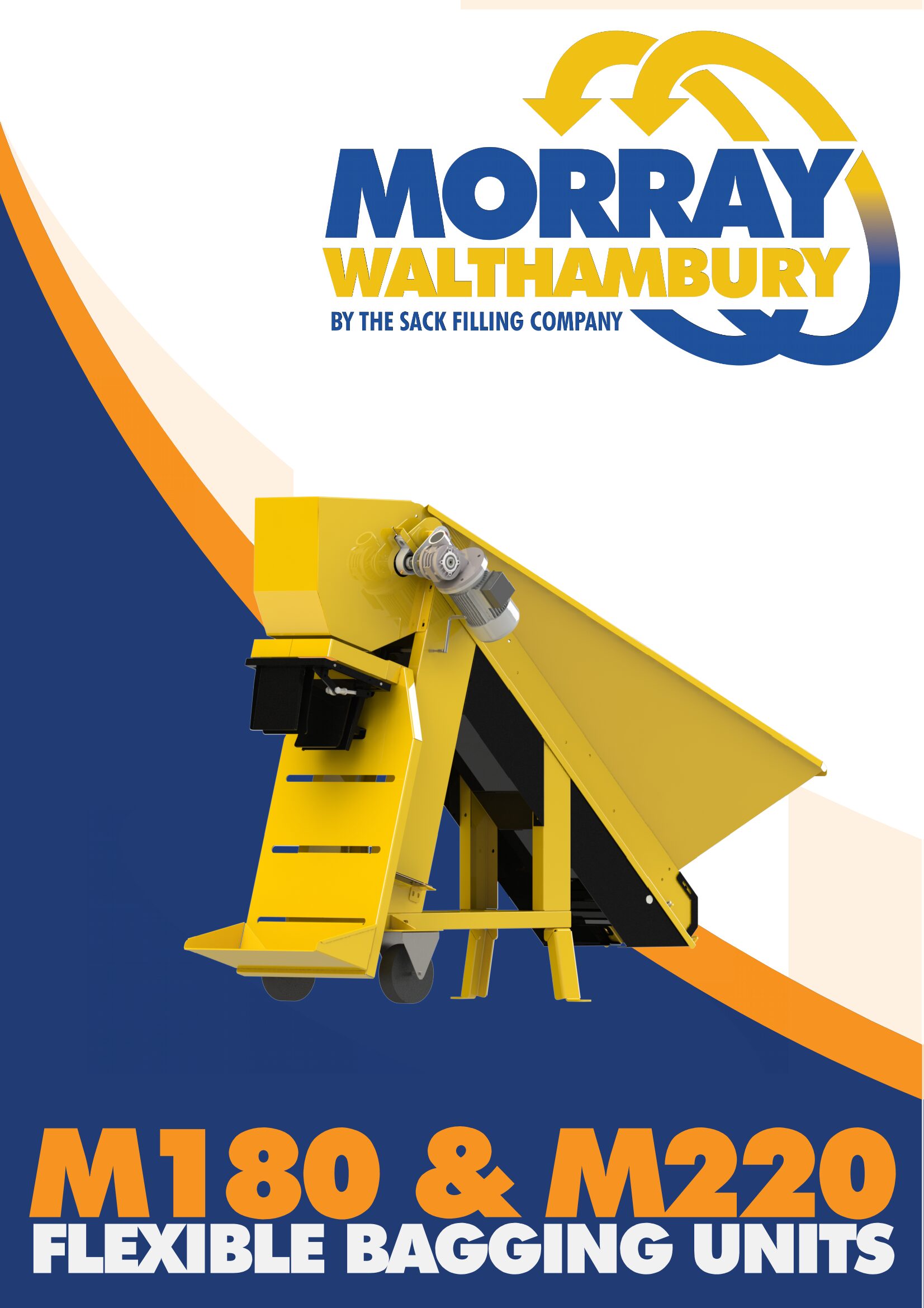

M180

The M180 is a simple, light weight Bagging Machine designed for low throughput manual bagging operations. Cost effective and versatile the M180 has a range of quick release attachments for various bag sizes and filling applications.

Key Benefits

- Twin belt unit with main and trickle feed for optimum accuracy

- Final bag weight ‘top-up’ by unique clutch mechanism

- Light-weight chassis allowing for a mobile weighing and bagging platform

- Up to 180 bags/hr

- Weight range from 5kg-50kg

Optional Extras

- Stainless Steel for food quality.

- Electronic Weighing System.

- M180QD model with alternative quick detachable accessories:

- Bag Clamp

- Pre-Pack Attachment

- Net/Jute Bag Holder

- Carton Filler Platform

M220 and M220QD

M220 and M220QD

Similar to the M180, the M220 offers a higher throughput while retaining the simple design of its smaller brother.

Key Benefits

- Single belt feed – available with sealed elevator for granular and fibrous materials

- Light-weight chassis allowing for a mobile weighing and bagging platform.

- Up to 220 bags hr.

- Minimum IP44 rating

- Weight range from 5kg-50kg

Optional Extras

- Stainless Steel for food quality.

- Electronic Weighing System

- M220QD model with alternative quick detachable accessories:

- Bag Clamp

- Pre-Pack Attachment

- Net/Jute Bag Holder

- Carton Filler Platform

M220/18

M220/18

M220 is a gross weigher for bulky products such as horse feed, peat or compost.

Key Benefits

- Single belt feed – available with sealed elevator for granular and fibrous materials

- Light-weight chassis allowing for a mobile weighing and bagging platform

- Up to 220 bags hr

- Minimum IP44 rating

- Chevron or plain style belt

Optional Extras

- Stainless Steel for food quality

- Sealed belt

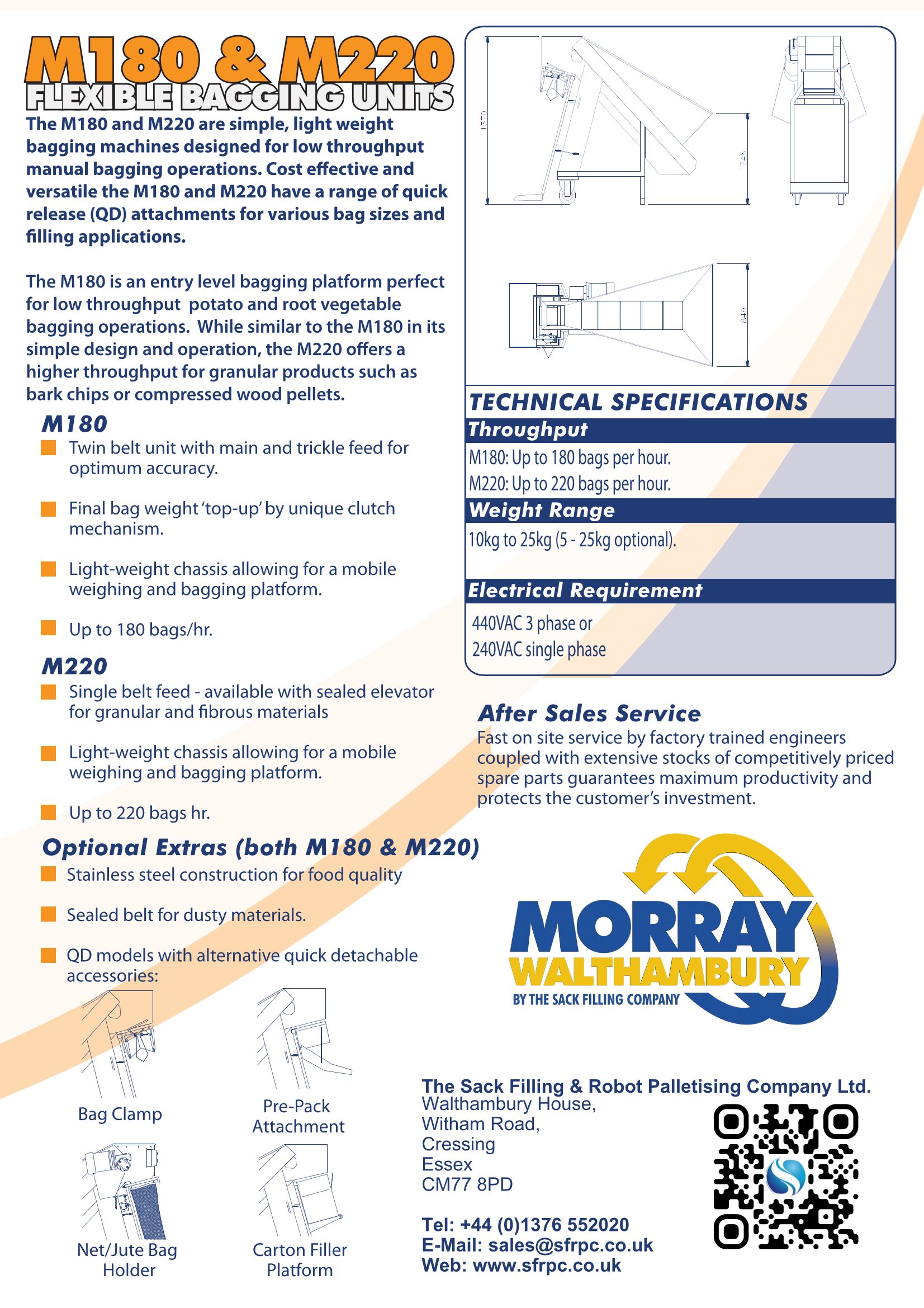

M520 & M530

M520 & M530

The twin head M520 and triple head M530 are a simple and effective method of bagging root vegetables in the field. Relying on only an air compressor driven off the main drive shaft of the harvester to operate. The M520 and M530 are designed to integrate into existing mobile harvesting platforms.

Models

M520 – Double Filling Head Version

M530 – Triple Filling Head Version

Key Benefits

- M520 – Up to 8 tons per hour

- M530 – Up to 10 tons per hour

- Suitable for 25kg weighments into paper and hessian bags

- Pneumatically operated bag clamps

- All contact parts rubber lined for complete product protection

Optional Extras

- Stainless Steel for food quality

- Electronic Weighing System

- Sack tray for lower weights or smaller bags

- NP7 fixed head and portable stitchers for bag sealing

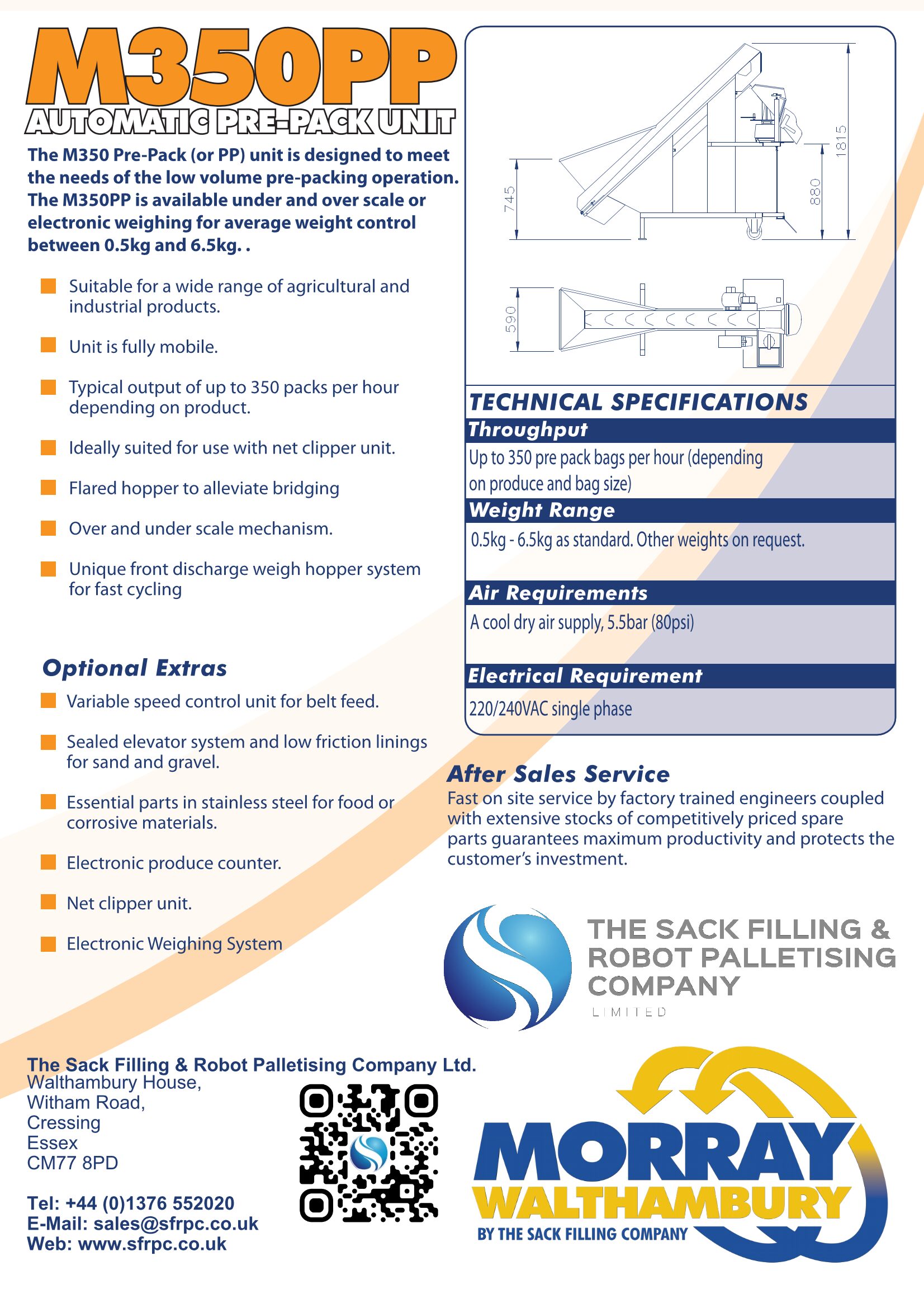

M350PP

M350PP

The M350 Pre-Pack (or PP) unit is designed to meet the needs of the low volume pre-packing operation.

Key Benefits

- Suitable for a wide range of agricultural and industrial products

- Fully mobile

- Typical output of up to 350 packs per hour depending on product

- Ideally suited for use with net clipper units

- Unique front discharge weigh hopper system for fast cycling

Optional Extras

- Variable speed control unit for belt feed

- Sealed elevator system and low friction linings for sand and gravel

- Essential parts in stainless steel for food or corrosive material

- Electronic produce counter

- Net clipper unit

- Electronic Weighing System

Automatic Gross Weighers

All Automatic Gross Weighers are fast, accurate, and reliable that feature:

- Pneumatically assisted trickle feed system, offers rapid and simple adjustment for varying products

- Quick release pneumatic bag clamps for all types of open mouthed sacks

- Compatible with our range of automatic sack placers, conveying and sealing systems

- 10 – 50kg weight range. Optional 5 – 25kg range

- Complete product protection, all contact parts are rubber or Perplas lined – depending on the product

- Non lube pneumatic components

- Optional stainless steel for food quality standards

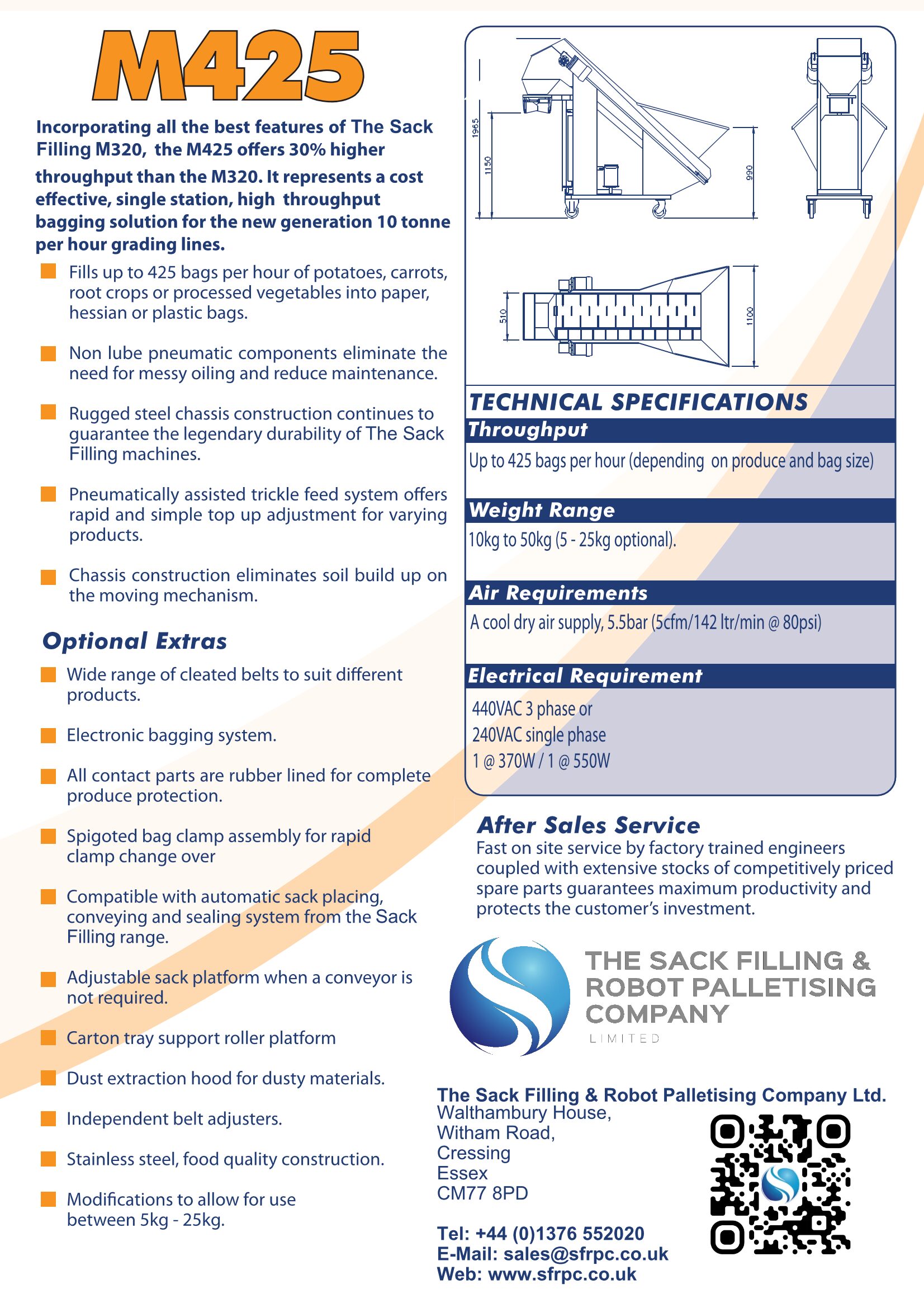

M425

M425

Incorporating all the best features of its predecessor the M320, the M425 offers 30%higher throughput than the M320. It also represents a cost effective, single station, high throughput bagging solution.

Key Benefits

- Chassis construction eliminates soil build up on the weighing mechanism

- Spigoted clamp assembly for rapid bag size change over

- Range of cleated belts for different products

- Up to 425 bags/hr depending on product and bag size

- Minimum IP44 rating

- Specialized versions available for solid fuels or potatoes and vegetables

Optional Extras

- Variable speed control unit for belt feed

- Independent belt adjuster mechanism

- Essential parts in stainless steel for food or corrosive material

- Electronic produce counter

- Net clipper unit

- Electronic Weighing System

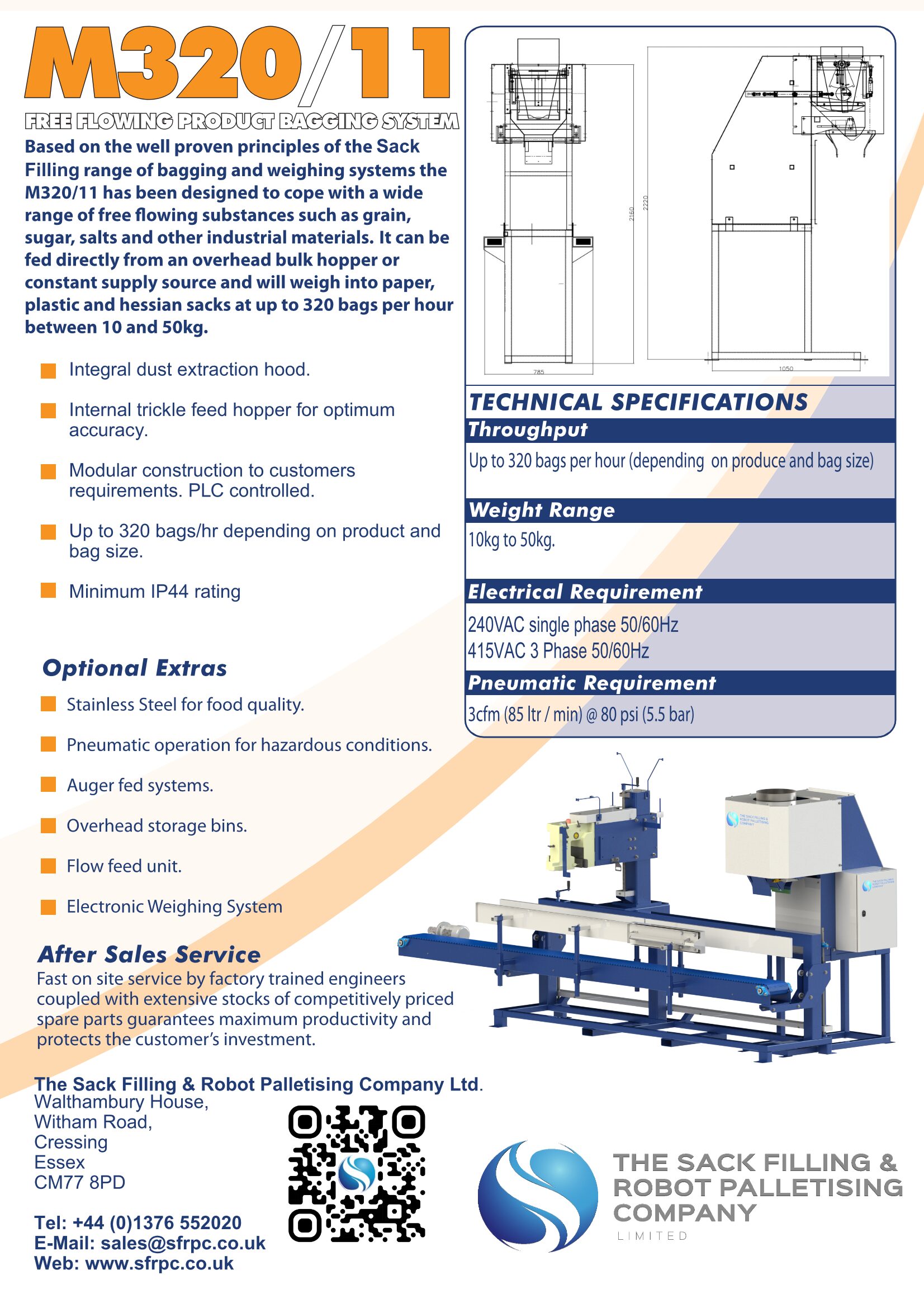

M320/11 Powder Bagging Machine

M320/11 Powder Bagging Machine

Based on the well proven principles of the Walthambury range of Bagging and Weighing systems the M320/11 has been designed to cope with a wide range of free flowing substances such as grain, sugar, salts and other industrial materials.It can be fed directly from an overhead bulk hopper or constant supply source and will weigh into paper, plastic and hessian sacks at up to 320 bags per hour between 10 and 50kg.

Key Benefits

- Integral dust extraction hood

- Internal trickle feed hopper for optimum accuracy

- Modular construction to customer requirements

- PLC controlled

- Up to 320 bags/hr depending on product and bag size

- Minimum IP44 rating

Optional Extras

- Stainless Steel for food quality

- Pneumatic operation for hazardous conditions

- Auger fed systems

- Overhead storage bins

- Flow feed unit

- Electronic Weighing System

T5000 (M320/18) Bagging Machine

T5000 (M320/18) Bagging Machine

Specially designed to fill a wide range of granular or fibrous materials into open mouthed bags and containers. Unique fill by weight or Volumetric fill bagging units form the centerpiece of fast and accurate pre-pack lines for maximum output with minimum labour.

Key Benefits

- Variable speed control feed belt to optimize throughput

- 320/18V – Volumetric version – 10 -100 liters, for peat, compost bark, bio-humus and other fibrous material. Possing action settles material in bag

- PLC controlled

- Up to 500 bag/ hour depending on product and bag size

- Minimum IP44 rating

Optional Extras

- Dust extraction hood

- Alternative angle elevator system with V form troughed belt

Automatic Net Weighers

Fast, reliable range of Bagging units for use with Cartons, Boxes and a wide range of different size/type Bags.

- Complete product protection, all contact parts are rubber or Perplas lined- depending on product.

- walthambury bullet Optional stainless steel for food quality or aggressive material requirements.

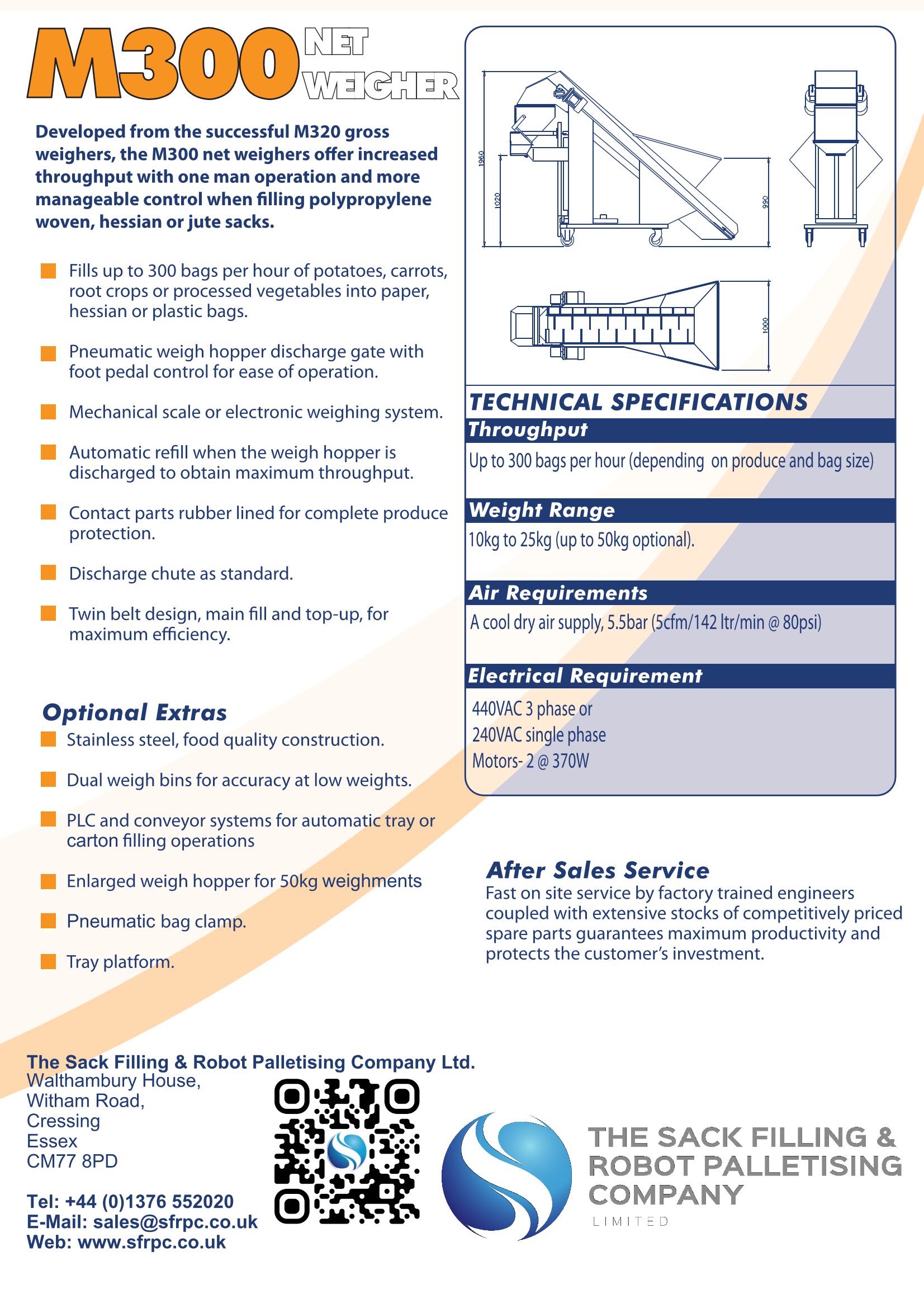

M300

M300

Developed from the successful M320 Gross Weighers, the M300 net weighers offer increased throughput with one man operation and more manageable control when filling Polypropylene woven, Hessian or Jute sacks.

Key Benefits

- 10-25kg weight range

- Chassis construction eliminates soil build up on the Weighing Mechanism

- Spigoted clamp assembly for rapid bag size change over

- Up to 300 bags/hr depending on product and bag size

- Minimum IP44 rating

Optional Extras

- Dual weigh bin for 10kg weighments

- PTFE liners for reduced dirt build up in weigh bin

- Electronic weighing system

- Wide range of cleated belts to handle different products

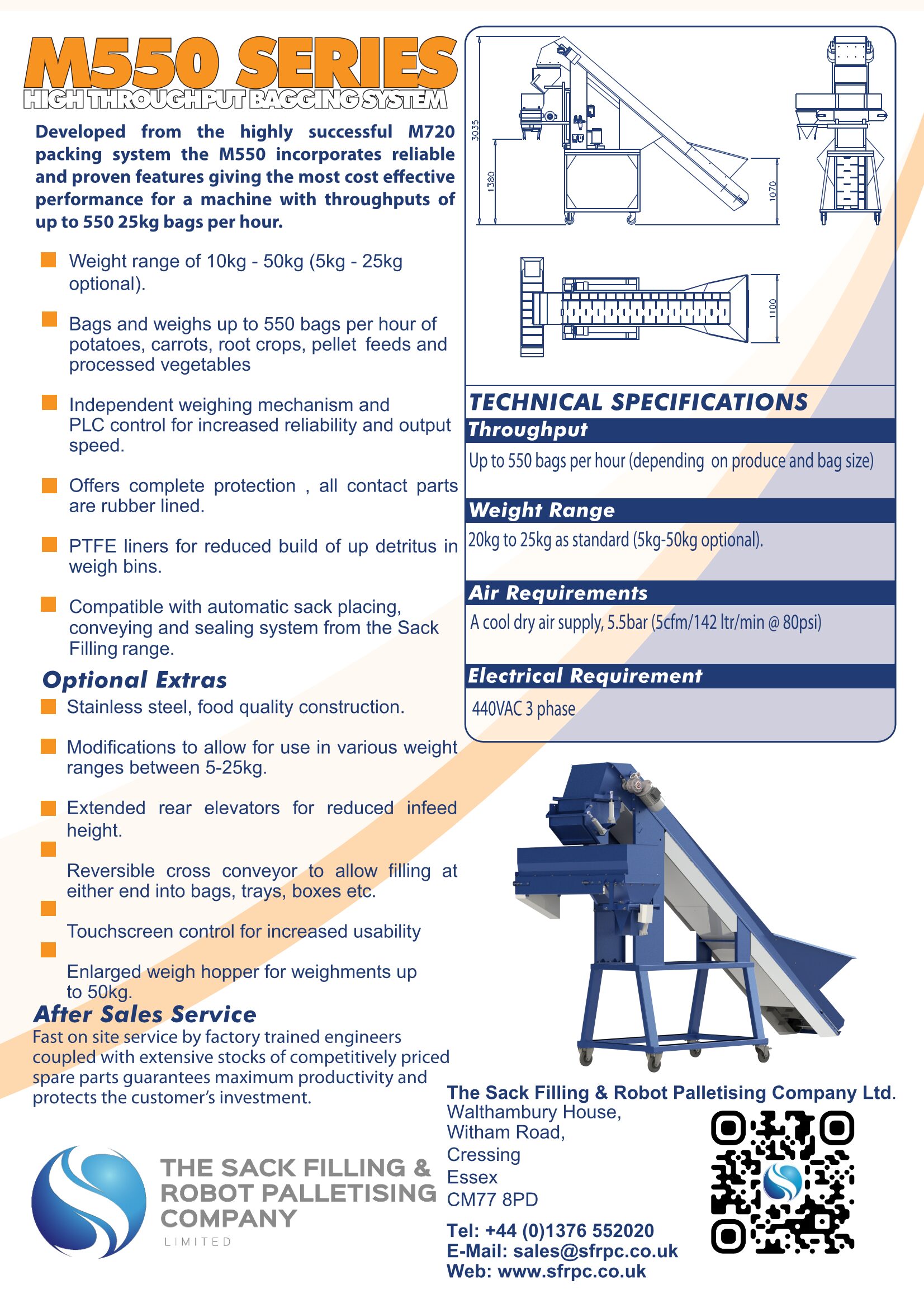

M1300

M1300

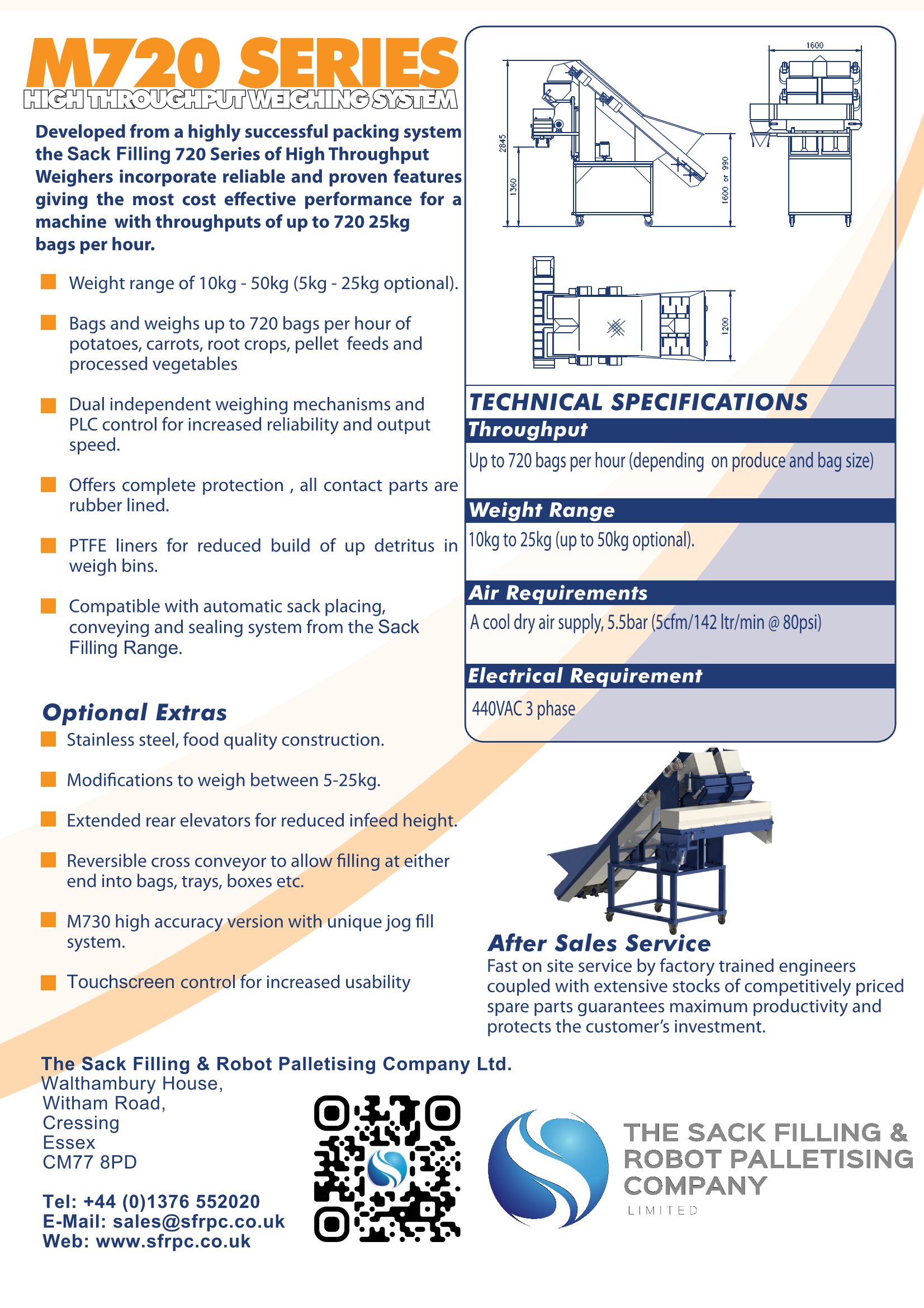

Developed from the highly successful M720 packing system the M550 incorporates reliable and proven features giving the most cost effective performance for a machine with throughputs of up to 550 25kg bags per hour.

Key Benefits

- 550 bags/hr at 10-50kg (625 bags/hr max. at 10kg weighment)

- Internal trickle feed hopper for optimum accuracy

- P.L.C. controlled

- Up to 550 bags/hr depending on product and bag size

- Minimum IP44 rating

Optional Extras

- Stainless Steel for food quality

- Electronic Weighing System

- Reversible cross conveyor to allow filling at either end into bags, trays, boxes, etc

- Dual weigh bin for 10kg weighments

- PTFE liners for reduced dirt build up in weigh bin

- Wide range of cleated belts to handle different products

M1800

M1800

The M720 Bagging Machine is designed to give extremely high throughput whilst remaining while remaining cost effective and simple to operate.

Key Benefits

- 720 bags/hr at 10-50kg (1000 bags/hr max at 10kg weighment)

- Variable speed control feed belt to optimize throughput

- P.L.C. controlled

- Minimum IP44 rating

Optional Extras

- Reversible cross conveyor to allow filling at either end into bags, trays, boxes, etc

- Dual weigh bin for 10kg weighments

- M720/06 Solid Fuel version

- PTFE liners for reduced dirt build up in weigh bin

- Electronic weighing system

- Wide range of cleated belts to handle different products

- Touch screen control

M1200

The M1200 High Speed Bagging Machine is The Sack Filling Company’s next generation of bagging machine.

Key Benefits

- Fully integrated filling and sealing platform

- Can fill bags from 5kg to 40kg

- High output, up to 18 bags per minute

- Reliable integrated heat sealer for plastic bags or stitcher for paper bags

- Self contained control with simple interface to downstream equipment

- Touchscreen interface with simple intuitive controls as well as in depth adjustment for more advanced users

- Massive 500 sack magazine

- Fully guarded for safety

- Can handle anything you throw at it! Wet and sticky sands, aggregates, animal feeds, grain, compost, woodchips, topsoil and many more products

Optional Extras

- Volumetric or electronic gravimetric weighing systems available

- Outfeed Metal detector with reject system to detect ferrous contaminants

- Bulk hopper and feed conveyor

- Access walkway for easy maintenance and cleaning

- Stainless steel contact parts

- Dust extraction for powdery products

- Customized touch screen with branding, company colors etc.

M600 Series Master Baler

M600 Series Master Baler

Designed to provide a consistent and gentle automatic means of packing and counting smaller pre-packs into paper, plastic or net outers. The patented Walthambury Master Balers provide unique cost saving solutions to the hitherto lab our intensive end of line packing operations.

Models

M602 – Paper & plastic bags.

M604 – Wicketted plastic & paper bags & integral Auto Sack Placer.

Key Benefits

- Unique patented pack lowering system avoids damage & jumbled packs

- PLC controlled for fast reliable operation

- Fully automated

- Instant change over to automatic packing combinations

- High Output, up to 80 pre-packs on wicketed plastic bags

Optional Extras

- Singulation system when used with multi-station bagging units

- Outfeed conveyor systems

- Fully automated collator closing system

- Non-standard sizes/packing combinations

- Touch screen interface